![]()

KAT®

P-Type, Programmable, Low Voltage

All Position,

Variable Speed Travel Carriage

![]()

KAT®

P-Type, Programmable, Low Voltage

All Position,

Variable Speed Travel Carriage

An Introduction to Gullco "Kat" Welding / Cutting Automation

Heart of the System

Gullco's

World Famous "Kat" Travel Carriage

What

is it ?

The

Gullco "Kat" carriage is essentially a motorized platform for welding guns

and cutting torches that travels along a special track. Its purpose is

to automate welding/cutting operations by moving the activated gun or torch

along the desired work path at the exact required speed. Result : manual

error and fatigue problems are eliminated .... specified quality and productivity

targets are repeatedly achieved.

How

Does it operate ?

The

electrically powered 'Kat' has a pinion drive gear that engages the rack

on the special Kat track, driving it forward or reverse at selected speeds.

A wheel guide system grips each side of the track enabling the Kat to travel

in any position... even upside down. An advanced micro-processor based

control provides precise forward/reverse speed settings for optimum automated

weld or cut results.

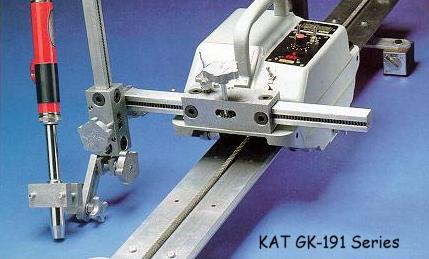

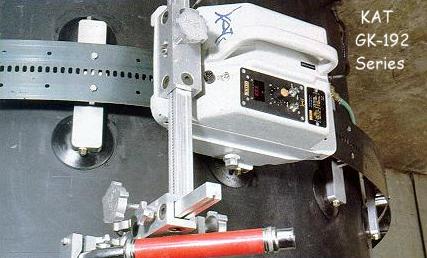

Gullco KAT GK-191

Series and GK 192 Series

Gullco

Kat Welding / Cutting Automation available in GK-191

Series for use with rigid

aluminium kat track and GK-192 series

fo use with flexible

spring steel flex-track

Oscillator

Travel

Carriage and Oscillator Controls are housed in this version of the Kat...

which combines welding gun oscillation movement with precise travel speed

of the Kat to produce many angular and step patterns. Some are shown at

right. An outstanding feature is the oscillator head. It is an independent

unit that can be easily adjusted side to side or forward / backward to

provide the most effective angle for multi-pass oscillation.

Auto-Weld

This

version of the Kat houses Kat carriage control and Auto-Weld control which

responds to adjustable timers and limit switches that are "tripped" by

actuators on the track. Various control settings and actuator positions

are combined to repeatdly perform automated weld/cut cycles including stitch

welding.

Torch

Indexing

This

version of the Kat is designed to automate overlay work. The system utilizes

a control that indexes tha rack arm at each end of the Kat travel path.

It responds to limit switches activated by adjustable track mounted stops.

GK-191

Series for use with rigid

aluminium kat track

GK-192

series

fo use with flexible

spring steel flex-track

Getting on the

Right Track

Gullco

Kat Track is available in Rigid

or Flex Track to

suit flat or curved surface applications... along with track mounting device

models for effective use on metallic or non metallic surfaces.