Hardox

wear plate meets strict demands on wear resistance. The unique combination

of consistent and high hardness, high strength and excellent toughness

makes the material well suited for a wide variety of applications.

Hardox

wear plate meets strict demands on wear resistance. The unique combination

of consistent and high hardness, high strength and excellent toughness

makes the material well suited for a wide variety of applications.

HARDOX®

Versatile

Wear Plate

Hardox

wear plate meets strict demands on wear resistance. The unique combination

of consistent and high hardness, high strength and excellent toughness

makes the material well suited for a wide variety of applications.

Hardox

wear plate meets strict demands on wear resistance. The unique combination

of consistent and high hardness, high strength and excellent toughness

makes the material well suited for a wide variety of applications.

Hardox is a quenched and tempered wear plate which has been developed at SSAB Oxelosund. The product was launched on the market in 1970 and has then been continually developed to meet the needs of our customers. Throughout the world, Hardox is now synonymous with high quality, good flatness and good surface finish.

Although Hardox plate is

3-4 times harder than ordinary high strength structural plate, its excellent

weldability and machinability properties make the material remarkably easy

to work with.

High hardness leads to a much longer useful life

Hardox

wear plate has been developed to withstand hard wear. The actual useful

life depends on the material in contact with the plate and the type of

wear to which the plate is subjected.

Hardox

wear plate has been developed to withstand hard wear. The actual useful

life depends on the material in contact with the plate and the type of

wear to which the plate is subjected.

In the handling minerals, the equipment is usually subjected to stresses of several types sliding and impact wear, often also combined with heavy deformation. These different wear conditions would usually demand materials with different compositions and different properties.

But Hardox wear plate with a hardness of 400 or 500 Brinell can withstand most types of wear.

The useful life of Hardox 400 may be up to five times longer than that of ordinary high strength structural plate.

In

certain cases, Hardox 500 can last more than three times longer than Hardox

400.

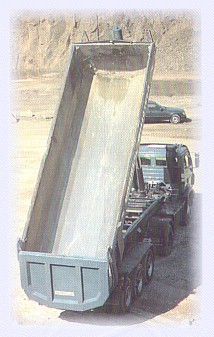

High strength - higher payload

Due

to its high strength. Hardox plate has better dimensional stability and

thus sustains a smaller amount of permanent deformation. Thinner plate

can also be used, which then results in a higher payload.

Due

to its high strength. Hardox plate has better dimensional stability and

thus sustains a smaller amount of permanent deformation. Thinner plate

can also be used, which then results in a higher payload.

The

excellent flatness of Hardox plate is also of great importance in the production

of tipper bodies, for instance.

Excellent toughness

Hardox is no ordinary wear plate. Its toughness is very high even under difficult conditions, such as at high rates of strain combined with low temperatures. This makes Hardox particularly resistant to impact.

The

properties are the result of an appropriate composition of the steel and

an optimized manufacturing process.

Easy on workshop

The

lean analysis of the steel used for Hardox plate results in a low carbon

equivalent. Hardox 400 and Hardox 500 have excellent weldability

and can be welded - to Hardox and to all ordinary weldable structural plate

- using any conventional fusion welding method. The

lean analysis of the steel used for Hardox plate results in a low carbon

equivalent. Hardox 400 and Hardox 500 have excellent weldability

and can be welded - to Hardox and to all ordinary weldable structural plate

- using any conventional fusion welding method.

Hardox 400 can be welded up to a combined plate thickness of 40 mm without preheating. |

Gas

cutting of Hardox plate is easy. As in all thermal cutting, a heat-affected

zone occurs at the cut surface. Gas

cutting of Hardox plate is easy. As in all thermal cutting, a heat-affected

zone occurs at the cut surface.

Thick

Hardox 400/500 should be preheated before gas cutting.

|

Purity, flatness and consistent quality make Hardox plate well suited for press and roll bending. |

Hardox

400 and Hardox 500 can be machined in all machine tools, using tools with

indexable inserts and in a stable, vibration-free set-up. Hardox

400 and Hardox 500 can be machined in all machine tools, using tools with

indexable inserts and in a stable, vibration-free set-up.

Hardox plate can also be drilled in a stable radial drilling machine. Using appropriate tools, Hardox plate can also be spot-faced and countersunk |

Specifications :

|

|

|

|

| Hardness |

|

|

| Thicknesses |

|

|

| Impact strength

Charpy V notch, longitudinal test piece at -40 C: |

|

|

| Strength

Yield strength Rp0.2 Ultimate tensile strength Rm Elongation A5 |

1250 N/mm2 10% |

1550 N/mm2 8% |

| Carbon equivalent

value

(CEV) for 20 mm thick plate |

|

|

| Stock Range : (Thickness) |

( 2.5 x 6 meters2 ) |

( 2.5 x 6 meters2 ) |